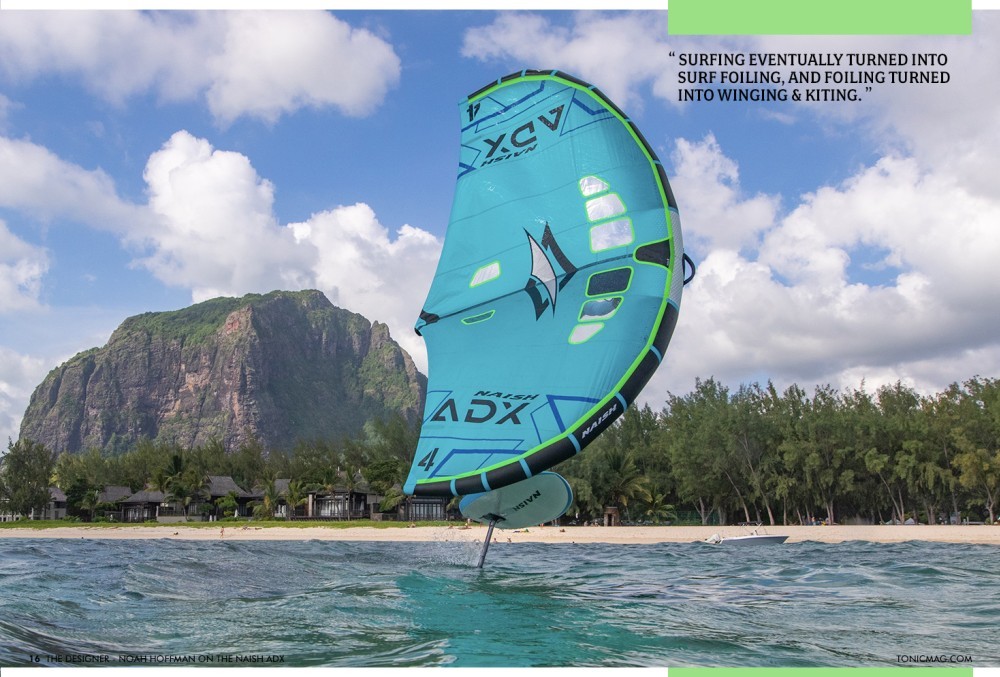

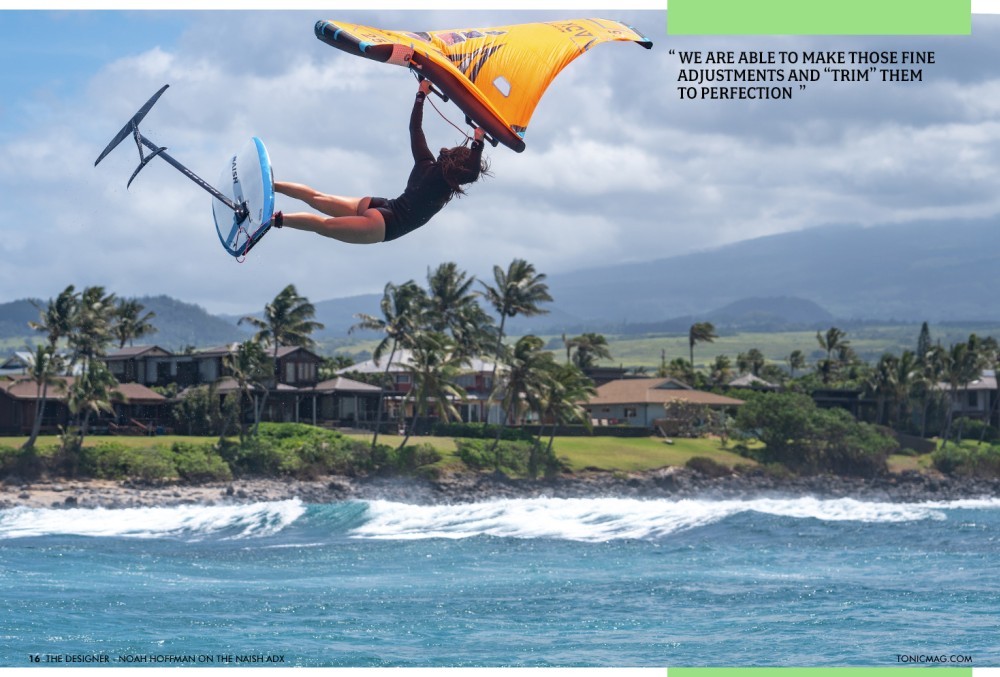

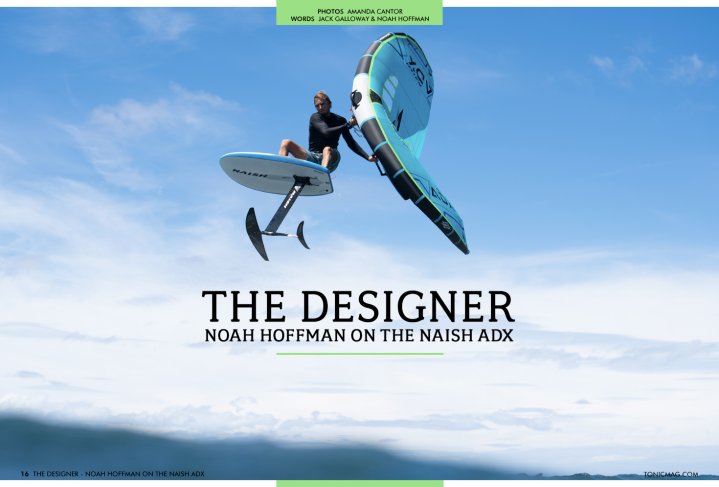

The Designer - Noah Hoffman on the Naish ADX

Issue 16 / Mon 29th May, 2023

The Wing-Surfer ADX, or Aero-Dynamic-Xtreme, is Naish’s latest and greatest piece of kit. We caught up with designer & all-round waterman Noah Hoffman to get the low down on the ADX.

Hey Noah. Thanks for taking the time to chat, we’re excited to find out all about the brand-new Naish ADX. Let’s start with a bit about you, you’re clearly a proficient foiler as well as a designer. What’s your background in both watersports and product design?

Well, I grew up in Kailua Oahu and have been on a board since before I can even remember. My background is in surfing, surfing eventually turned into surf foiling, and foiling turned into winging & kiting. Designing for me started at a very young age, I always enjoyed making things and working with my hands. My grandpa helped me shape my first surfboard when I was 13 and throughout the years I have done many projects to find new ways to express my creativity. I followed in my father's and grandfather's footsteps and got my degree in Mechanical Engineering. Setting me up very well for a job as a designer, having both passion for the sports and technical knowledge from my schooling.

Sounds like it worked out! What led you to work with Naish?

One of my long-time family friends is Des Walsh who has been with Naish for over 20 years. Growing up in Kailua we would always go into the Naish Shop with my dad and spent a lot of my young days on the beach hiding under kites and watching my dad windsurf. Because of this, in my eyes when I started doing wind sports Naish was the cool brand. After I graduated from school, I was onboarding with a different company outside of the watersports realm when Des called my Dad to see if I would be interested in a position at Naish. Going this route was one of the best decisions I have made in recent years. Being able to do what I enjoy in and out of the water for a career is super rewarding.

I'm glad to hear it. Hawaii must be a great place for product testing & development.

Hawaii is an amazing place for product testing and development. There is pretty much something you can do in the water every day wind or no wind. My girlfriend and family still live on Oahu so I do a lot of traveling between the two islands and that helps get a good range of conditions for testing.

How many of you were there in the team for the ADX and what’s the process like start to finish in creating a product like this?

The core test team includes myself, Robby Naish, Michi Schweiger, and Austin Kalama. We also use a variety of riders as well as customers to cover all aspects of what the wings need to achieve in terms of their performance and target market.

For a product like the ADX we are able to start with a baseline which is always the product that we created previously. We then narrow down what direction we would like to go in and through lots of prototyping and testing, we move to achieve that goal. A good relationship between us and our factories is an essential part of that process. It was tough through covid as traveling was difficult through most of the development process so constant communication was necessary to achieve the results we wanted.

I bet. How much of a part do your professional riders have in testing gear & giving you feedback?

They are definitely a big part of the testing process. Robby Naish, our product manager Michi Schweiger and myself collect the feedback from our testers and discuss how to apply it to the development of the product and eventually bring it into production. It was really important to us that we not only use our top team riders but get balanced feedback from a variety of riders with different skill levels and different expectations.

The ADX has a higher dihedral than previous Naish wings. Can you explain the reason behind this?

We changed the geometry a lot from the previous MK4, one of the biggest shape changes was increasing the wing span making the wing a higher aspect. The added dihedral was an essential part of adjusting the wings handling. The higher wingspan requires that the wing balances a bit more over your hand and is not ridden as vertically as the MK4. This makes it so you don’t have to worry about your wingtip hitting the water when you are riding around. There is so much positive lift in the wing that it feels like it wants to fly out of your hands. The dihedral gives the wing the balance to stay neutral in the air, essentially auto balances itself. Making tacks and gybes easier as the balance allows you to focus on projecting through your turn and not where the wing is positioned.

Naish has placed a big emphasis on the canopy tension of the ADX. How did you and the other designers achieve this?

One portion to achieve the canopy tension is also connected to the dihedral which allows us to keep even tension through the entire canopy section. Another factor was that it was possible again to fine-tune patterns directly at the factory once the covid restrictions were lifted.

What’s the reason behind the strengthened Plasma Dacron material on the central ’T’ part of the strut & wing?

The idea behind the t-bone construction came from previous wing failures across the market. The strut and middle section of the wing takes the most stress and sees the most failures. With the additions of rigid handles, we wanted to ensure that we gave the wing enough structure so that you get the full benefit of the direct feel provided by the handles. We also wanted to give the airframe a little extra structure in the center while still keeping the weight down and allowing the tips to twist off making for a comfortable ride.

How does a designer like yourself go about deciding on the balance between durability & weight?

This essentially gets directed by the market needs. The team now has several years of experience on the wings with a track record that shows us what is doable in terms of material choice. In addition to that we have decades of sail and kite making, allowing us to create the right balance between performance and a wing that will last for many seasons.

The Naish ADX has an interestingly shaped curve strut. I’m excited to find out how it feels when we get one on test but in the meantime can you explain why it’s there?

The curved strut was designed for a more comfortable hand position when riding. This was achieved by putting the rider’s body in the middle, so that they can sheet in automatically through body position and not by pulling with their arms.

In addition, it creates a more favourable hand position. The curve of the strut in combination with our handle design aligns the rider’s arms and wrists making it easy and comfortable to hold on even in really powered conditions. For example, if the strut is straight then your front hand will have a slight angle at the wrist and the power distribution will be more straining on your front hand. With the curved strut, your front hand aligns straight and you essentially have a more ergonomic hand position that lets you apply more power and that doesn’t tire out your wrist and forearm.

Well, that makes sense to me! Am I right in saying the rigid handles are a teardrop shape? Is this to help with grip and control?

Yes, the handles have a teardrop style shape a flat and corners on the top side so that it fits into your fingers perfectly. They are designed so that you can hold onto the wing with just your fingers. The shape creates a great hold that takes little effort to maintain during long sessions. Whereas, a shape like a pure oval or a circle you have to actively grip to keep it from slipping out of your hands. The size and thickness of the EVA was also tuned to be comfortable to hang on to with as little effort as possible.

I’d say brands are about 50/50 on whether their wings have windows or not. Can you explain why you felt it was important to stick with them?

The discussion about windows will probably be never-ending. But having the chance to at least have a glimpse of what is going on downwind of you and avoid a collision is a convincing reason for us. The windows towards the back hand allow you to check the area before gybing without having to sheet out. The front windows give the rider the chance to see what's downwind of them slightly ahead. Visibility and safety get more and more important in more and more crowded spaces on the water especially when dealing with different wind sports where the riding angles differ dramatically.

Finally, can you talk us through the size range and any changes in design for the relevant sizes?

We offer the ADX in a full-size range with 2.0/2.5/3.0/ 3.5/ 4.0/ 4.5/ 5.0/ 5.5/ 6.0 and 7.0

The flow through the sizes carries the same basic style and concept. The sizing of the LE and strut and the connected PSI recommendations are the biggest adjustments next to adjusting the aspect ratio. Smaller wings for example get too twitchy if the strut is too short. Through testing all sizes individually, we are able to make those fine adjustments and “trim” them to perfection before going into production.

Thanks for filling us in on all the details Noah. We look forward to getting one on test!

By Jack Galloway