The Interview - Armie Armstrong

Issue 18 / Tue 21st Nov, 2023

For this issue’s ‘The Interview’, we got to speak to the man himself, Armie Armstrong! Armie opens up about extraordinary childhood, sailing around the world with his family, his journey in watersports, his love for the ocean and his introduction to kitesurfing and foiling. Armstrong's love for foiling and watersports shines through in the interview - Read the full interview exclusively in Tonic Mag!

Welcome, Armie! We're thrilled to have you here. Please tell us about the beginning of your journey in watersports. What inspired you to start?

To make a long story short, I was lucky to grow up on a sailing boat with my family. We sailed around the world for a few years when I was very young, and I learned to walk on the boat somewhere in the Pacific Ocean! Probably because of that, I have always had a strong affinity for the ocean or any body of water. I experience severe withdrawal symptoms if I'm not in, on, or under the water regularly. Growing up on a sailboat is one of the best ways to learn about how objects function in the natural world. During school, I was introduced to whitewater kayaking and competed at a national level. I was deeply affected by how energy and water move in powerful rivers. You become part of the current with the small kayaks we were using. While studying for my science degree at university, I worked part-time as a whitewater raft guide and enjoyed windsurfing as much as possible. And then kitesurfing happened…

During your time as a keen kiter, were you ever involved in any competitions in the early days?

Not really, although we did make a video for the NZ edition of Red Bull King of the Air when the legendary Flash was in his prime; kitesurfing was more of an adventurous sport for me in the early days as I chased uncrowded waves. It was all new and exhilarating, with massive development all the time, much like foiling now. I vividly remember Lou Wainman boosting straight over me and a couple of friends at Sprecks on Maui when we were windsurfing there in 1999. That was the turning point. Within 6 months, we had all sold our windsurfing gear and were happily getting trained by the early 2-line inflatable traction (“tractor”) kites. Foiling, to me, is similar in that it offers new perspectives on water sports and a sensation of sheer freedom.

One of the first to embrace foiling with a kite, what got you interested in taking the sport in a new direction?

As a sailor, kite foiling immediately appealed to me because the foil allowed me to sail at such great upwind angles. It enabled me to explore much larger areas than twin tips permitted. Foiling made kiting a genuine sailing sport for me, which is now evident with kitefoiling's inclusion in the 2024 Olympics. The sensation of foiling is also incredibly addictive. I just couldn't get enough, much to the amusement of my father, as I would kite around him on his yacht during family holidays. He definitely wondered when I would have any time to 'grow up' and find a real job!

New Zealand is certainly out on a limb. Was it hard to get into new disciplines when the gear wasn’t so readily available and there wasn’t a crew of people going in the same direction?

There is often a lag with new cultural or sporting activities coming to New Zealand. We have a real sense of doing it our own way, and while that is cool, it can be limiting to new things sometimes. As you say, gear is harder to come by for us, especially in the earlier days of a new sport. I was lucky that Daniel Kereopa had an ancient boot-binding tow foil rig handed down from Laird that was collecting dust in his shed. When kite foiling started, we took that setup to our kite spot in Raglan. That was how I had my first foiling experience. It was love at first flight! To this day, the Mike Murphy-inspired sit-down foils are a good learning platform as they are very thin, produce quite manageable amounts of lift and regain that lift immediately if they come out of the water. This lack of “ventilation” incidentally inspired some of our MA foil designs. These older sit-down foil designs need a lot of rider input to rise - that’s good when you’re trying to throw it around like a surfboard.

Is that what turned your focus to producing your own gear?

Limitations always lead to innovation, and plenty of people in NZ simply made their own gear - kites, boards, and foils. A few have even grown into leading international brands. I was so hooked after those first flights that I saved my pennies and bought a good kite foiling-specific rig. I wanted to immediately jump on the foil, but being a bit of a gear thrasher and that foil not being designed for jumping, I was always in the workshop repairing it. Growing up on the water, with a boat builder as my grandfather and an architect as my father, I knew my way around tools and started experimenting with my foils. I was mates with Rob Whittall from kiting missions together in NZ. Rob’s an inspirational individual and a designer who always sees far outside the walls of the box. I floated the idea of making an all-sport foil setup that was much stronger and wouldn’t require constant repairs when pushed hard. He loved the idea and was keen to support my mad dream, so we began. We didn’t know how hard that job would be or where it would take us, but we gave it a try!

You were a big fan of SUP racing and had some amazing results; what was your favourite race and why?

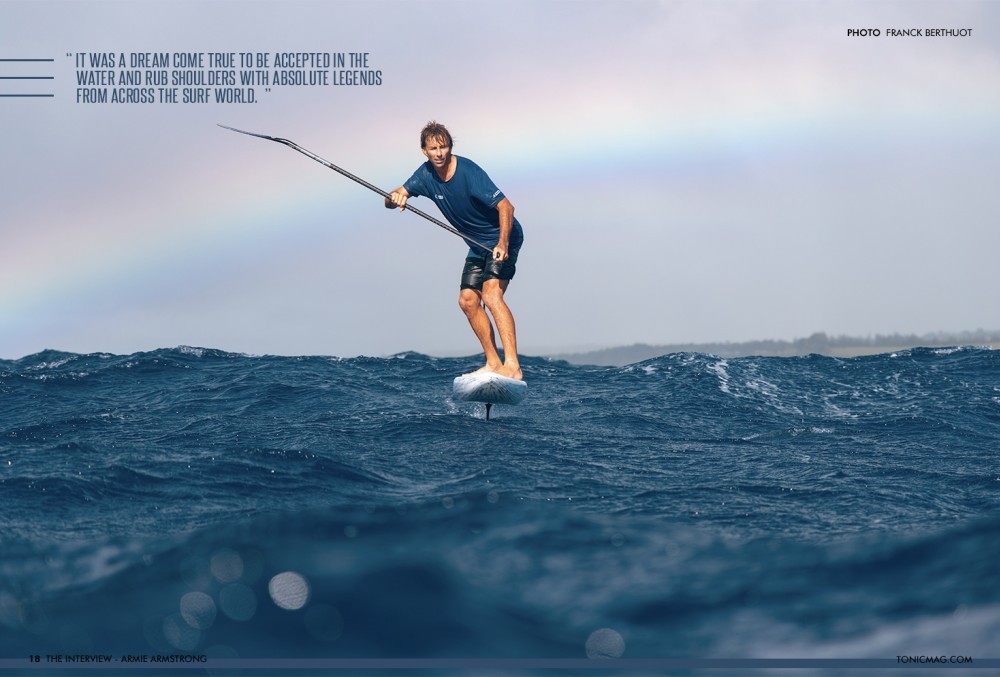

My favourite race has always been the Pailolo Channel (Maui to Molokai) because it is such an epic stretch of ocean! The Molokai2Oahu World Championship is the most rewarding as it presents a challenging channel. These are closely followed by the early Battle of the Paddle events in Hawaii, organised by Sparky and Gerry Lopez. The Battle of the Paddle was legendary because surf racing was so enjoyable and it attracted surf legends from all levels in Hawaii at that time. It was a dream come true to be accepted in the water and rub shoulders with absolute legends from across the surf world. Everyone was thrilled to be part of it, and that inclusiveness also extended to the early days of kiting, which were booming here in New Zealand.

As one of the first to think about putting a foil on a SUP, where did that idea come from? Was there a particular event or instance that made you believe a foil would be better?

I wanted to beat the younger SUP racers who were dominating at the time! I didn't care how, or whether it was within the rules. A foil seemed to be the obvious answer! I was experimenting with a massive handmade prototype foil that my dad helped design with the aim of achieving easy, low-speed flight.

Around that time, Kai Lenny made one of his incredible viral videos - it must have been early 2016. He was successfully downwind foiling on Maui's North Shore with a prototype foil rig. I immediately booked a flight to Maui to learn how to do it myself! We were completely hooked, and for about a year after that, we worked tirelessly on homemade mutant prototypes in our garage as we traveled the world chasing SUP races. Our intention was to create something that even non-professionals like me could easily use. Such good times!

Foiling has expanded so much in recent years; what’s your favourite foiling discipline, or is it condition-led?

That is a tough choice as I love them all! It depends a lot on the conditions. But in reality, these days I’m using whatever prototypes need to be tested for the refinement process, and with our expanding product ranges to cover these cool new additions to foiling, there isn’t much time for non-test foiling; luckily, I love my job!

This year, that meant a heap of downwind SUP foiling in Hawaii. It was amazing to be there working on gear as that was one of my dreams when I started out. Like many people, I have also gone through phases with my foiling. Initially, kite foiling was my obsession, but then I got into SUP surf foiling and didn’t kite so much. Tow foiling also became a significant part of our development process as you can get tons of time on foil and it's the easiest way to back-to-back test the many different variables in prototype testing. Plus, it’s great fun! I don’t dock start much, and to be honest, there simply isn’t enough time in the day for me to also go prone surf foiling. Luckily, a big team of amazing riders is working with us to test the gear. Aidan Nicholas spent much time testing our APF pump foils. Oskar Johanssen, Jeremy Wilmotte and Reo Stevens are busy testing the equipment in waves. Cash Berzolla, James Jenkins and Tatiana Grant test our winging gear - to name just a few!

Armstrong is known for making some of the highest-quality gear on the market. Was that always a focus for you as a brand?

It’s always our goal to make the best gear we possibly can through a continual research and development process. We love all forms of foiling, so this passion drives us to make gear that feels great to us. Like with anything where design is evolving, at times, it can seem like the more you learn, the more you realise you have left to learn! That can seem frustrating, but it’s extremely exciting as it means there is still so much development to come that will take the foiling journey to exciting new places soon.

We’re proud to have built a foiling-dedicated brand from the ground up as the sport itself grew. It’s almost surreal to take a step back and look at the depth of world-leading design consultants we can call on today in our daily pursuit of improvement. There are just so many cool projects on the go. It’s an incredible ride, and I sincerely thank all our customers who enjoy the gear as much as we do!

Is it hard to balance the quality, cost and margins to keep the company in business, or do you purely focus on quality first and let the rest follow?

We focus consistent quality on a daily basis and recognise that there is always room for improvement. I think that everyone has experienced the effects of the crazy rollercoaster of the past few years, especially within the fast-paced business industry that has been constantly evolving. Our main drivers are quality and innovation. Even though I am extremely passionate about foiling, it requires a lot of hard work and dedication. One of the most significant factors in our success is the incredible team that I have partnered with and built. The management has now been taken to a whole new level with outstanding people in key leadership roles. This means everyone in the business can focus on their passion to build the best product - the rest takes care of itself.

Foils have seen some massive changes in recent years, and you were always at the forefront of that development; in hindsight, did the sport dive down the super high aspect rabbit hole too fast?

It’s a natural human instinct to push boundaries with new tools, particularly in an exciting new sport with a spotlight on more experienced riders. One issue can stem from people overestimating their progress level and getting on gear too soon that is too advanced for them. In foiling’s recent evolution, there’s been a good mix of stable, easier foils along with more radical high-performance designs. Looking back to where it all began with the crazy thin, solid alloy Mike Murphy sit-down foils bolted to the feet of big wave riders chasing gloriously impossible dreams; and somehow pulling it off! Some HA foils are advanced/expert-oriented and out of reach for many riders, but that does not mean they should not be developed. The progress made on earlier HA foils has led us to mind-bending downwind achievements and has positively influenced future designs. So, no, I believe all development is beautiful and necessary. It’s impossible to build something to perfectly suit all riders, all the time. It’s essential to look carefully at the ranges of foils on offer and choose what best suits your skill level, foiling discipline, and the conditions where you ride.

Your MA series of wings is getting huge acclaim now; what makes them different from the other offerings on the market?

It is a simple thing- they are so bloody fun to ride! These foils were developed primarily for the wing and tow disciplines. They are made to be ridden with power, allowing a rider to direct that power from a wing and/or wave with precise and easy control. The ease with which these foils carve turns is addicting. Our primary development goal with these foils was to make the most forgiving, best ventilating (where the foil comes out of the water) foil possible. When paired with the Surf, Flow, Speed or Dart stabilisers, the MA foils come alive when pushing hard turns in the pocket or skipping across the surface with a wing before instantly reconnecting to the flow and riding away. This means recovery from breaches; riding through whitewater or landing airs becomes a fun component of foiling instead of fearing breaking through the water’s surface.

Your foil system is very different to everyone else out there. How hard is it to produce, and why aren’t other brands copying it?

Ha! Yes, it is not an easy system to manufacture, and we are very proud of the consistent quality our manufacturing team has achieved. We always work to improve the details of the system wherever possible. Materials and layups are a significant part of testing and prototyping. We also work with several expert manufacturing consultants to analyse our processes and techniques - some exciting developments are coming soon!

Our core design concept has several key elements that create that smooth “X-factor” feel our foils have in the water. A round mast bottom bracket and fuselage shape move smoothly through the water, primarily through turns, no matter what angle the foil is on. The curves and fairings at the front and rear disperse loads as evenly as possible into the mast fibres. This enhances the ride characteristics and longevity of the mast itself. Over the years, we have fully optimised key layup details for consistent, industry-leading construction quality. We use a 100% titanium threaded rod in the fuselage core, which pairs with our titanium and 316 hardware for lightweight, corrosion-resistant connections. We feel very strongly about every customer who has supported the brand, so modularity through commonality in design is very important. The A+ System allows anyone with an existing setup to quickly put on one of our latest components because the titanium core carbon fuselage system and foil/stabiliser fittings have remained the same. It’s awesome to see how riders progress when they bolt on a new foil or stabiliser. It’s all about having great sessions together for maximum enjoyment in the water.

You’ve never made an aluminium mast; what's the thinking behind that? Do you think that alienates some of the market at the lower end from your products?

We’ve made focused decisions about materials with the priority to consistently deliver first on our high quality and performance standards - this has consistently resonated with our customers. It’s great that there are so many choices in the foil market these days; it’s good for the growth of the sport, us and other brands.

High Modulus Carbon is a buzzword now; how much of a difference does it make? Is stiffness the ultimate goal with foiling, or is a bit of flex sometimes a good thing?

As with most things, there are various opinions on this topic. The devil is in the details, with many factors to consider. There are only a handful of fibre manufacturers in the world, so the basic fibre quality from all suppliers is pretty consistent. There are pros and cons to different modulus fibres for the fibre types. High modulus adds stiffness but is more brittle and needs to be mixed properly with intermediate modulus for acceptable durability. The actual fibre orientation is equally important to the modulus in any layup. And then there is the complex world of resin systems and prepreg quality. That’s a long story, but to keep it simple…we comprehensively track and test every batch of prepreg fibre we use. We have our own independent testing facility where we conduct standardised tests on the fibre batches before they make it to production. Composite industry experts have reviewed these tests to ensure we’re using the best material we can to maintain product quality. There are some areas where stiffness and solidity are essential, particularly at the mast top and board connection areas. The highly robust top half of our masts, combined with our boards’ custom carbon foil tracks bonded to the deck with our dual carbon PVC Innegra stringers, means rider inputs are maximised for a smooth-flowing ride. The lower portion of any mast will always flex to a certain degree, and riders have varying preferences here. Regardless, the flex must be consistent and return to its original form evenly. That’s achieved by using good layups and materials.

The new A-Wing XPS is also getting rave reviews right now; that was a collaboration with some of the best wing and kite designers. How long did that process take, and was the goal to produce the ultimate all-round wing across a range of disciplines?

We’re really stoked with how this wing came out! It took eighteen months of development with our new design team and was a fun process where we learned a lot and tested many different ideas. It was very rewarding not to put ourselves under too much time pressure so we could explore all our options during the development process. The project direction evolved into making an all-round wing anyone could have a blast on. We know winging has massive growth potential, and the sport will specialise in more and more defined disciplines, but it’s still such a fun freeriding sport. The XPS is a wing that can do it all for most riders.

You’ve used some new materials in the new wing. Was the material choice a big part of the project? Did you test the yellow stuff (Alulla), too?

Yes, we tested everything we could get our hands on! In the end, we settled on a new hybrid material selection for the XPS construction. UPE and Aluula are both excellent materials for specific applications like ultra lightwind riding, but in development for everyday riding, we preferred the feel of more Dacron. Plus, there’s a price benefit for customers. The hybrid Dacron UPE and DLE130 construction of the XPS is perfect for an all-around wing for most riders in most real-world riding conditions.

The pre-twist aspect of the design builds the wing so that it will perform when filled with wind and under pressure. Is that a difficult process to model and then create in the factory?

That was quite a challenge to get right and meant a lot of prototypes were necessary to tune each parameter properly. It also meant a lot of sleepless nights working on tuning tensions and angle details to ensure the result was as good as we could achieve. There are a few more elements to designing preloading than just twist. A preloaded airframe means that the whole wing span is engaged and evenly loaded when flying in use. A sail or wing that is evenly loaded across the entire span is the most efficient way to move through the air.

It feels like you’re on a roll at the moment with the gear; the new DW board seems to be the weapon of choice for many riders out there. Was that a project very close to your heart as one of the sport's pioneers, and what makes the board different and easier to ride than some of the other options?

I’ve loved downwind SUP racing for a long time, and when foiling downwind became possible around 2016, I was completely hooked. That was the catalyst for Armstrong to develop and grow as a foil brand. I was completely obsessed and chased downwind conditions worldwide to ride with the best and learn as much as possible. It’s awesome to see this side of foiling finally emerge as a core part of sport. Some of the best moments of my life have been flying downwind in the most beautiful places on the planet (ex Na Pali Race 2017). Stability and ease of use were at the top of the design list for our Downwind board range. Then, easy acceleration, good release and consistent tracking. You can’t push hard for takeoff if you are unbalanced and unable to put in a good paddle stroke. Our tried and tested proprietary construction A+ System carbon foil track system is critical to how the board and foil feel together when up and flying. Interestingly, though, perhaps the most significant thing we’ve discovered about the DW boards is how fun they make lightwind winging! Massive wings and big foils are no longer needed with a DW board.

Do you think that DW can become a mainstream sport, and if not, what's stopping it from being as big as winging or kiting?

Downwind foiling is more demanding of the rider than winging or kiting in terms of skills and picking the right conditions, but the feeling of freedom is so addictive!

With the developments in board and foil designs, I think the gateway to learning DWing is much more open and will continue to grow along with the riders and gear. It may never get as big a following as kiting or winging, but you never know - the sensations of freedom and adventure on a big DW run are hard to compare. Downwind is the adventure side of foiling that will attract new people to these fantastic moments of flight that we all love.

Armie, we know you are an exceedingly busy man, so thanks so much for taking the time to talk to us; here’s the last question…if you could do one sport for the rest of your life, what would it be?

Foil, anywhere, anytime, anyhow! Mahalo for the great questions.

Videos

By Rou Chater

Rou Chater has been kitesurfing for over twenty years, paddleboarding for the last six years, and was there testing the first wingsurfer from Naish in Tarifa when it arrived on the continent. He is passionate about riding waves and exploring new places. As the publishing editor, he oversees everything at Tonic but also our sister magazines IKSURFMAG and IMB. He's been on the water since he was born and has never looked back, in the winter you'll find him chasing swells in the Caribbean and during the summer he can be found all over Europe at various SUP, Kitesurf and Mountain Bike events getting features for the magazines.