AFS Factory Tour

Issue 24 / Wed 4th Jun, 2025

We caught up with Gwen Le Tutour fresh off a visit to the AFS Foils factory in Brittany, France. Gwen shares his first-hand impressions of AFS’s rider-driven approach to innovation, sustainability, and craftsmanship. From a factory that feels more like a community hub to prototypes developed in just 48 hours, Gwen offers an inside look at what makes AFS unique—and why he continues to ride their gear by choice, not contract!

Hi Gwen, it’s great to have you here, and we can’t wait to hear about your recent visit to the AFS Foils factory! What was your first impression when you arrived and had Tanguy le Bihan show you around?

Last year, while I was in Crozon for the Crozon Foil Festival DW race in France, AFS invited me to visit their factory, which is only 30 minutes away from Crozon. Since I grew up in Brittany, it’s especially cool that AFS manufactures their foils and boards in the region. When I arrived at the factory, Tanguy greeted me warmly. I appreciate how approachable and passionate he is, and he’s also quite funny. I’ve spent some time with him in Hood River during AWSI, and whenever you’re with him, you know you’ll have a great time!

AFS is known for producing everything in-house. What was it like to see the full process, from design to final product, all under one roof?

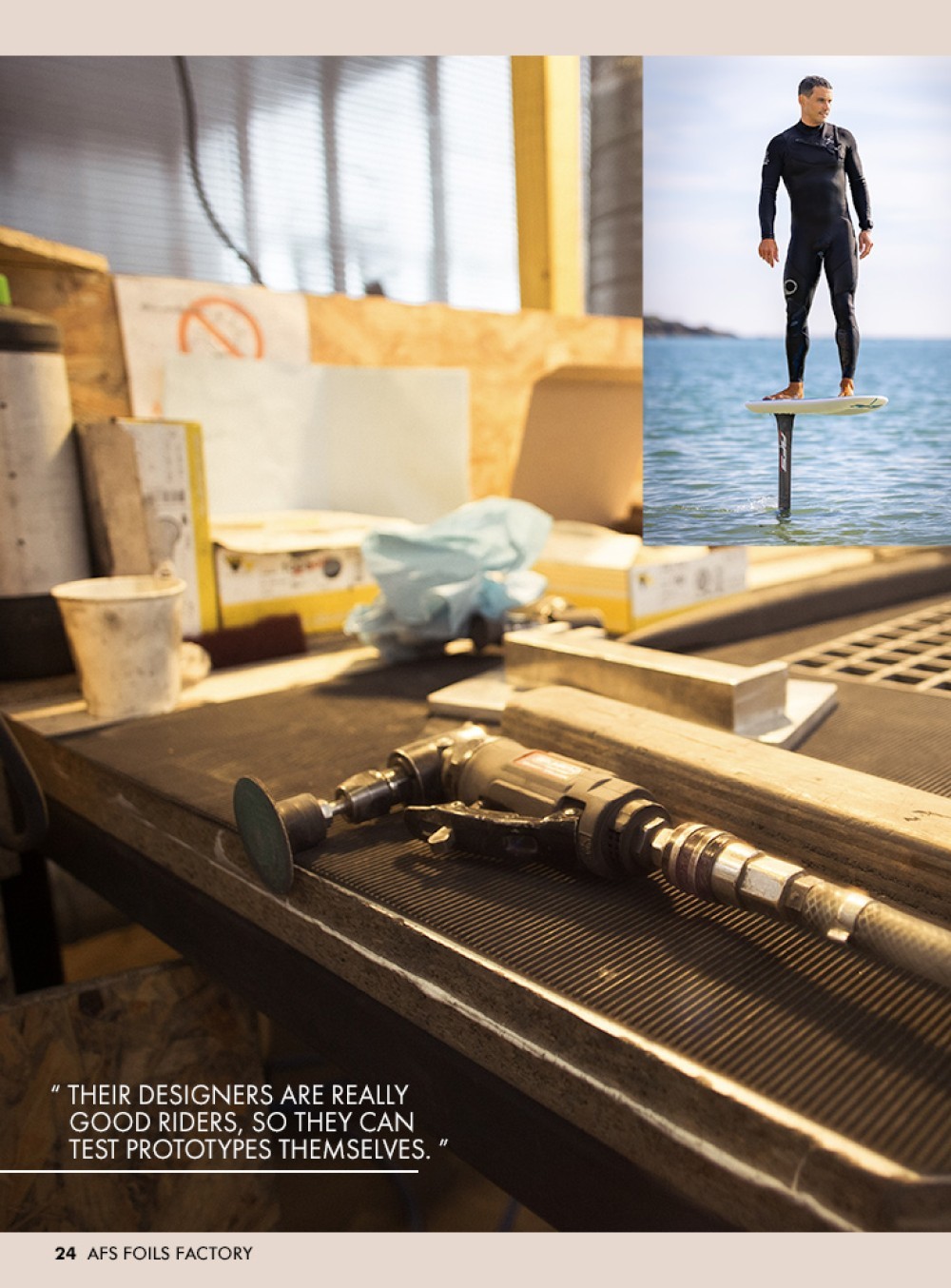

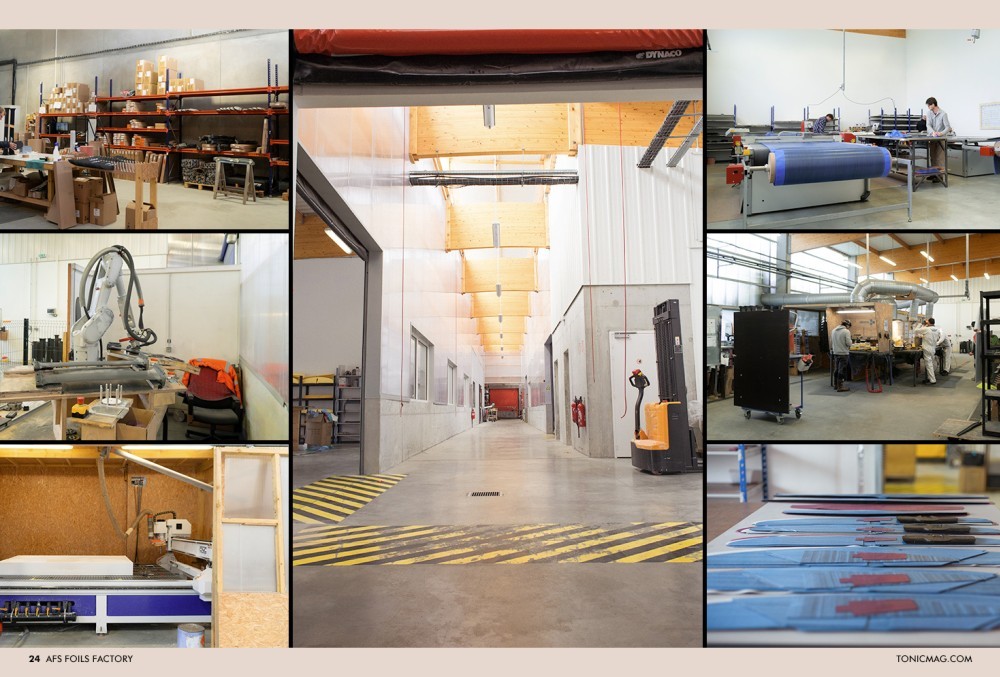

The factory is impressive, super clean, and well-organised. The ceiling has many windows, making the space bright and spacious, which is not what I expected from a factory. The entire crew working there are all riders themselves. As soon as you enter the parking lot, you see tons of wetsuits drying on people’s cars, which shows the team’s passion for riding! In one area, you can meet the company's owner and the workers who are sanding foils. Everyone eats lunch at the same table, creating a big family atmosphere. The vibe during lunch was very French, haha!

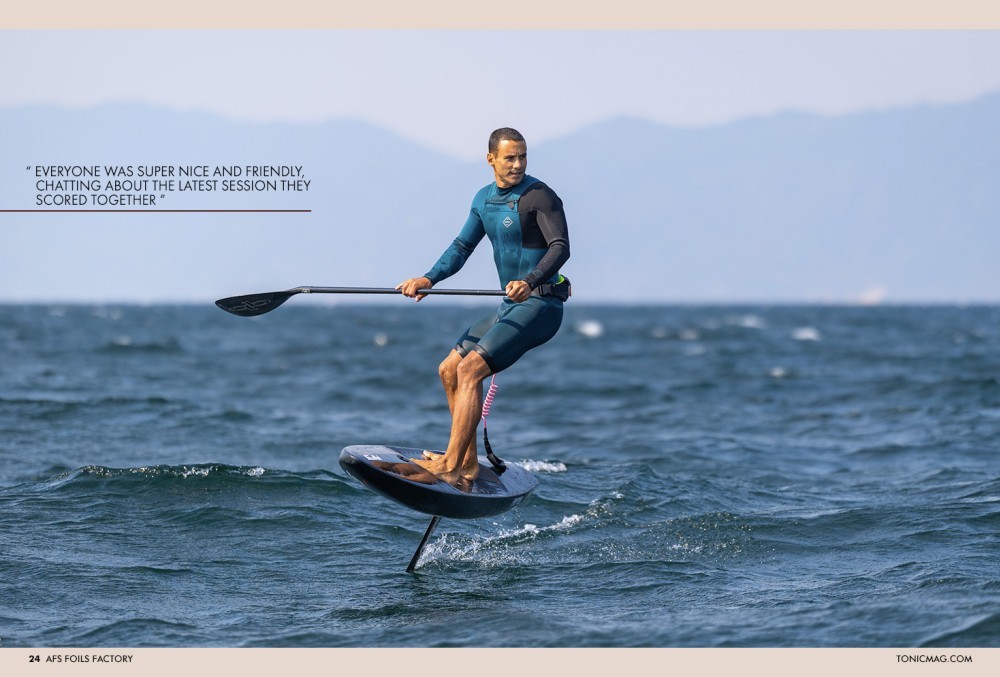

Everyone was super nice and friendly, chatting about the latest session they scored together or about family, etc.... it was a place I feel I would enjoy working at myself. The vibe during lunch was very French, haha!

How difficult was it for the team to set up the factory in France? Was it an expansion of AHD or a new building and project?

I’m not entirely sure, but Tanguy emphasised that setting up the factory in Brittany was very important to him. He mentioned several reasons for this decision, including the need for control over production, maintaining quality and standards, minimising the environmental impact of production in Asia and the shipping process, and providing local jobs.

How important is it for a brand to have full control over production?

Obviously, the control of quality and standards is a big thing. But also the reactivity to demand. When producing overseas, you often have to produce in bulk. AFS is able to adapt the manufacturing volume to the demand and not overproduce, flooding the market with products people don’t want.

Did you get a sneak peek at any new prototypes?

I noticed a few things that looked very interesting, but they weren’t ready to share any information yet!

Would you like to share any interesting conversations with the engineers, designers, or riders?

I admire how Tanguy and the design team focus on creating products they genuinely want to use themselves, rather than just aiming for increased sales. This passion behind the brand instils trust in the products they design. For example, monobloc foils, like silk and pure foil, prioritise performance without compromising.

What surprised you the most about how AFS approaches product development and testing?

One, their designers are really good riders, so they can test prototypes themselves. Two, they have the factory right there, so they can literally go from idea to working prototype in 48 hours -that is crazy!

You’ve ridden a lot of gear—how does the AFS product range compare in terms of performance and feel?

I am neither an ambassador nor a sponsored rider, so I have no obligation to ride AFS and no special incentives; I pay for my gear. For downwinding, I’ve primarily been using the 800 Pure. It remains one of my favourite foils of all time due to its thin profile, which provides an unparalleled glide experience. For winging, my go-to has been the 700 Enduro, which offers a fantastic combination of carving, speed, and glide.

Additionally, I’ve spent considerable time on the Blackbird V2 and V3 downwind boards. They are fast and incredibly fun!

Hand finishing the products requires very skilled and time-consuming work. Will there always be a need to hand-finish the foils?

I think machines will be able to handle a big part of the finishing stage in the future. I believe AFS is working on an alternative solution to hand finish, which could potentially increase production capacity while maintaining their high standard.

Can you say something that most people wouldn’t expect about the AFS factory?

The AFS factory is very different from what most people imagine when they think of a factory. With its solar panels, skylights, and cheerful employees, it feels more like a place where you would want to hang out with your foiling friends!

How has this visit shaped your perspective or deepened your connection with the AFS brand?

I feel a strong alignment with AFS on many levels. First and foremost, the quality and performance of their products make every session incredibly enjoyable. Beyond that, I appreciate AFS's commitment to sustainability, which is very important to me beyond just our sport. Additionally, my personal connection with the people and the location of AFS truly seals the deal. I am a huge fan of AFS, so thank you for being such a fantastic brand!

Thanks Gwen!

Thanks, Jen!

Videos

By Jen Tyler

Italian/Egyptian Jen Tyler grew up on the sandy beaches of the Red Sea and has been on the IKSURFMAG & Tonic Mag team since 2017.