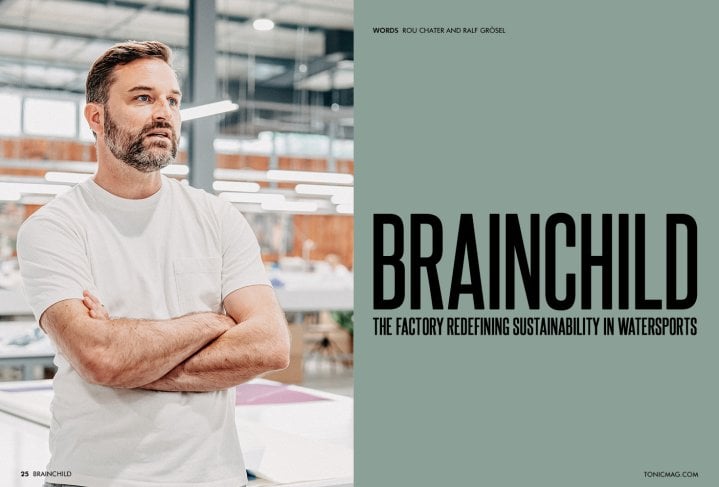

Brainchild: The Factory Redefining Sustainability in Watersports

Issue 25 / Wed 3rd Sep, 2025

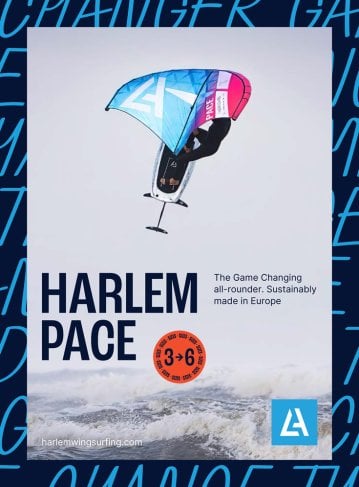

For Ralf Grösel, founder of Brainchild Production, the future of watersports is about more than performance; it’s about responsibility. From solar-powered factories to digital printing and eco-materials, Brainchild’s partnership with Harlem Kitesurfing shows that innovation and sustainability can go hand in hand. Find out all about it in the exclusive feature:

When you think about the future of watersports, you might picture lighter, stiffer equipment, futuristic materials, and riders pushing ridge limits even further. However, for Ralf Grösel, founder of Brainchild Production, the future isn’t just about performance. It’s also about responsibility.

Sitting in his office in Germany, Ralf reflects on the journey that began in an empty warehouse in North Macedonia just a few years ago. “The entire Brainchild project is kind of nuts, really,” he laughs. “We started from nothing, with no one around who knew how to manufacture these products. It was insanely complex, but ultimately it created the freedom I’ve always been looking for.”

That freedom is being put to use not only in technical innovation but in tackling one of the sport’s biggest challenges: sustainability. And nowhere is that commitment clearer than in Brainchild’s partnership with Harlem Kitesurfing, producing their flagship wing, the Harlem Pace.

What started in North Macedonia as a 1,500 ft laboratory to test new production techniques has now grown, with a further 3,000 ft manufacturing facility being created. All the ideas they perfected on the smaller project will be scaled up to the larger manufacturing facility. Once it’s built, the focus at the Branichild Lab will be on exploring new techniques and materials not only to improve the performance of the products they build but also to further enhance their green credentials.

A Factory Built on Green Principles

Unlike the vast majority of kites and wings built in Asia, Brainchild was designed from the ground up with sustainability in mind. “First of all, the most important thing is that we try to do everything we can to avoid waste”, Ralf explains. “If we can avoid creating waste or pollution, then we are trying to do so.”

The factory runs on solar power. Panels on the roof generate enough electricity not only to cover production needs, but also to feed back into the grid on weekends. “The grid is the battery for us,” Ralf says. “We are more than ninety percent solar right now, and with the new facility, we will actually create more energy than we consume.”

It’s a simple yet radical idea: don’t just offset emissions; don’t just plant a tree somewhere else in the world - design the system so that the emissions aren’t created in the first place.

Local Materials, Smaller Footprints

That philosophy extends to every stage of production. Brainchild deliberately sources as much as possible from within Europe. “When we started, we said: okay, we now have the chance to be in Europe and find European suppliers. That was the first aspect, getting materials without having them shipped around the world.”

Some components still have to come from overseas, but the focus is always on reducing unnecessary transport and cutting the footprint of every wing produced. “For example, if we have to use plastic, where’s the plastic coming from? Can we use recycled plastic? Yes, what is the benefit? If not, do we have a source next door? For example, our plastic bags, which are made of an LDPE4 material, come from a facility next to our production facility.”

It’s the kind of detail most riders never think about when they pick up their gear. But for Ralf, it’s part of building a culture where sustainability isn’t an afterthought; it’s built into the company's DNA.

Digital Printing and the Harlem Pace

The Harlem Pace is a direct beneficiary of this approach. Walk down any beach and you’ll notice it instantly, the bold digital graphics that make Harlem wings stand out. That look isn’t just a style choice. It’s a sustainability decision.

In the old days, colourful designs meant cutting multiple panels of fabric, dyeing them, stitching them together, and wasting vast amounts of offcuts and water. Brainchild does it differently. “We just purchased white material,” says Ralf. “Some of the materials are not even bleached; they’re natural white, which saves even more water. Then we print digitally with eco inks, and it’s far more efficient.”

The digital printing process uses four times less water than traditional methods. It also allows Harlem to unleash a visual identity that’s as vibrant as the riders using their gear. The result is a product that is lighter, cleaner, and far less wasteful.

Lighter, Stiffer, Smarter

Of course, sustainability only works if the gear performs, and in this respect, the Harlem Pace delivers in spades. At the heart of its design is Brainchild’s unique ProWeld technology, which bonds seams without the need for traditional stitching. The result is a lighter, stiffer frame that directly translates into improved performance on the water.

“From a designer’s point of view, it’s a massive step,” Ralf says. “I can create a better frame. The leading edge and struts are lightweight due to ProWeld, which also makes them cost-effective. It’s not as expensive as some of the exotic laminates out there, and ultimately, our products are even lighter.”

In practice, that means Harlem riders experience a wing that reacts faster, holds its shape longer, and weighs significantly less than many competitors’ products. It’s an innovation born from Brainchild’s laboratory, but it dovetails perfectly with the factory’s eco ethos: less material, less weight, less waste.

Sustainability Beyond the Environment

Ralf is quick to point out that sustainability isn’t just about carbon footprints or energy bills; it’s also about people. At Brainchild, the workforce is viewed as an integral part of the ecosystem. “We have a fantastic production manager, Svetlana, who is going to take over the new manufacturing site,” he says. “I have full trust in her. The idea is that I’ll focus on what I’m good at, pushing limits and innovating, and the team will run production.”

There is a huge focus on keeping the team happy and engaged at Brainchild; sustainability is also about the staff. It’s a vision that includes fair working conditions, stability, and growth opportunities for the people who build the gear. That’s a world away from some of the anonymous mass production lines elsewhere.

Why It Matters

For wingfoilers, all this adds up to more than just a feel-good story. It means that when you pick up a Harlem Pace, you’re holding a wing that reflects not only cutting-edge design but also a commitment to doing things better.

“It’s not okay if you are in a position to do something better and you just ignore it,” says Ralf. “That’s not how we think. If you can, you have to.”

The Pace is a performance wing, yes, it’s fast, stable, and incredibly light, but it’s also proof that the watersports industry can evolve towards a greener future without sacrificing fun.

Looking Forward

As Brainchild expands into a new, larger facility, the opportunities for innovation, both technical and ecological, are only set to grow. Ralf is already excited about new material developments, particularly in winging. “We have projects in the pipeline to change winging,” he teases. “I can’t say too much yet, but we’re waiting for some new materials to come in that will make a big difference.”

What’s certain is that sustainability will remain central to everything Brainchild does. Solar power, local sourcing, digital printing, waste recycling, and fair workplaces - it’s a holistic model that challenges the industry to do better.

And with Harlem wings like the Pace leading the charge, riders can already feel the difference every time they hit the water.

The story of Brainchild and Harlem is more than just a case study in eco-conscious manufacturing. It’s a glimpse of what the future of our sport could look like: where performance innovation goes hand in hand with environmental stewardship, and where every jump, every carve, and every glide comes with the knowledge that the gear beneath your hands was built to leave as light a footprint as possible.

As Ralf Grösel puts it, “As long as I can see a happy face on the beach, then there will be life in the market. And I want those smiles to come without guilt, for the rider, and for the planet.”

By Rou Chater

Rou Chater has been kitesurfing for over twenty years, paddleboarding for the last six years, and was there testing the first wingsurfer from Naish in Tarifa when it arrived on the continent. He is passionate about riding waves and exploring new places. As the publishing editor, he oversees everything at Tonic but also our sister magazines IKSURFMAG and IMB. He's been on the water since he was born and has never looked back, in the winter you'll find him chasing swells in the Caribbean and during the summer he can be found all over Europe at various SUP, Kitesurf and Mountain Bike events getting features for the magazines.