Sunova

Brand

Sunova Style

This board has a super interesting shape. For me, it was reminiscent of a Donald Takayama style performance nose rider longboard. It has a huge squared off spoon like nose with loads of bottom shape, straight parallel rails with lovely rounded tops into a sharper edge, going down to super pinched-in, performance looking pintail. In terms of finish, it looks...

2 years ago

James Casey shares his Thursday thoughts on the skills you should work on before heading out for your first Downwind Foil in this episode of...

2 years ago

Thursday thoughts with James Casey! Get your tickets to the screening of The Downwinder at the Collaroy Cinema, on June 24 here!

4 years ago

Could this be the future of downwind foiling? Wing upwind, deflate and downwind.

4 years ago

This downwind run is enough to inspire you to give downwinding a go. Its got great footage and awesome conditions and the new RS foils!...

4 years ago

Another James Casey video where he really shows the appeal of wing foiling in waves, he even has the local surfers watching him. See more...

4 years ago

For the most of us this is real world surfing and it really showcases surf foiling. Less than average waves and some magical rides. One...

4 years ago

The GWA Wingfoil European Championship was a huge success and although the weather made the first day tricky the competitors were keen to put on...

4 years ago

Turn your wave session into a downwinder. Looks like a dreamy session withnot a huge amount of swell but ideal to get up and commence...

4 years ago

James Casey is making tricky conditions look epic again. Light winds, a big wing and a small board looks so appealing except the rocks, they...

4 years ago

Winging has made it possible to enjoy wind powered sports in what would have been almost a right off for you r session a few...

4 years ago

Wing Foil Upwind, Deflate whilst going Downwind, Pump Up and Repeat. Is the future? Mini down winders achievable without the extra admin of vehicles and...

4 years ago

James Casey making it look so easy on his wing. Awesome laid out turns on these rolling sets. First try on the Slick out the...

Issue 10

We chat to Brian Grubb, founder of the Foil Surf Racing League, a unique & exciting event that recently took place in Cocoa Beach, Florida

Issue 9

James Casey is a font of knowledge when it comes to downwinders. Whether it be SUPfoil or winging he’s been at forefront from the start. Jack Galloway catches up with James to learn more about him & his down winding skills.

Issue 3

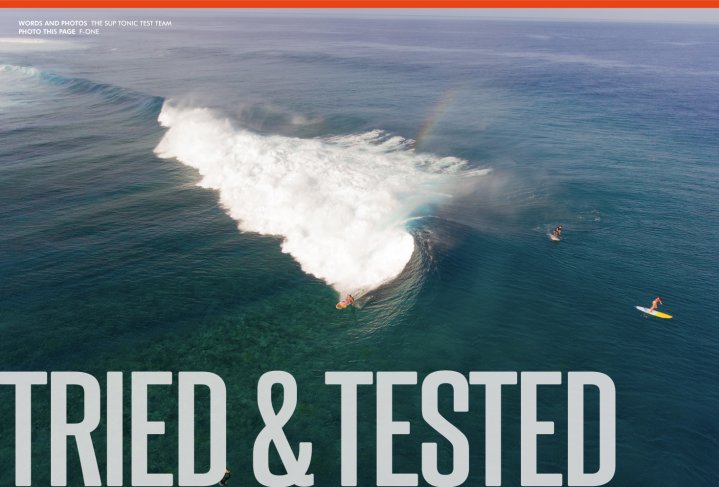

We’ve some of the new 2017 gear on test this issue, including boards from F-One, RRD and Sunova along with paddles, clothing and footwear from Body Glove, Prolimit and RRD.

Posts we shared on our Facebook Page over the last 2 months

SUNOVA Surfboards by Bert Burger: Shaper of the year 2007.

Creator of the Parabolic Balsa Rails Construction.

Contact us: [email protected]